Understanding HRC, Toughness, and Sharpness in Knives

When evaluating a knife, many people focus on a single number: HRC. While hardness is important, knife performance is actually the result of a balance between hardness, toughness, and sharpness. Understanding how these properties interact helps explain why some knives cut better, last longer, and fail less often.

What Is HRC?

HRC (Rockwell Hardness Scale – C scale) measures how resistant steel is to indentation.

- Higher HRC means harder steel

- Lower HRC means softer steel

Most knives fall between 52 and 64 HRC, depending on steel type and heat treatment.

How HRC Affects Sharpness

Harder steel can support a thinner cutting edge, which allows:

- Higher initial sharpness

- Better edge retention

- Reduced edge rolling during use

Typical knives optimized for sharpness operate around:

- 58–64 HRC

However, hardness alone does not guarantee sharpness.

Edge geometry, grind quality, and heat treatment play equally important roles.

How HRC Affects Toughness

Toughness is the ability of steel to resist:

- Chipping

- Cracking

- Breaking under impact or lateral force

As hardness increases:

- Toughness generally decreases

This means very hard blades can chip or crack if used improperly, especially under impact or twisting loads.

Knives that prioritize toughness usually operate around:

- 52–57 HRC

These blades may require more frequent sharpening but are more forgiving in use.

The Trade-Off: Hardness vs Toughness

There is always a balance between hardness and toughness.

| Property | Higher HRC | Lower HRC |

|---|---|---|

| Edge Sharpness | Higher | Moderate |

| Edge Retention | Longer | Shorter |

| Toughness | Lower | Higher |

| Chip Resistance | Lower | Higher |

The best knives are not the hardest, but the ones with the right balance for their intended use.

Sharpness Is Not the Same as Hardness

Hardness supports sharpness, but it does not create it.

Sharpness depends on:

- Edge angle

- Grind consistency

- Steel microstructure

- Final finishing and polishing

A well-ground knife at 56 HRC can cut better than a poorly ground knife at 62 HRC.

Why Heat Treatment Matters

Heat treatment controls:

- Grain size

- Carbide distribution

- Internal stress

Two knives with the same steel and HRC can perform very differently if heat treated incorrectly. Proper heat treatment improves:

- Edge stability

- Chip resistance

- Sharpening consistency

In many cases, heat treatment matters more than steel type.

Typical HRC Ranges by Use

- General-purpose knives: 56–60 HRC

- High-performance cutting knives: 60–64 HRC

- Impact or heavy-use knives: 52–56 HRC

Matching hardness to application is key to long-term performance.

Conclusion

HRC is an important measurement, but it should never be considered alone.

A high-performing knife requires:

- Sufficient hardness to hold a sharp edge

- Enough toughness to resist failure

- Proper geometry and heat treatment to tie everything together

In knife design, balance always outperforms extremes.

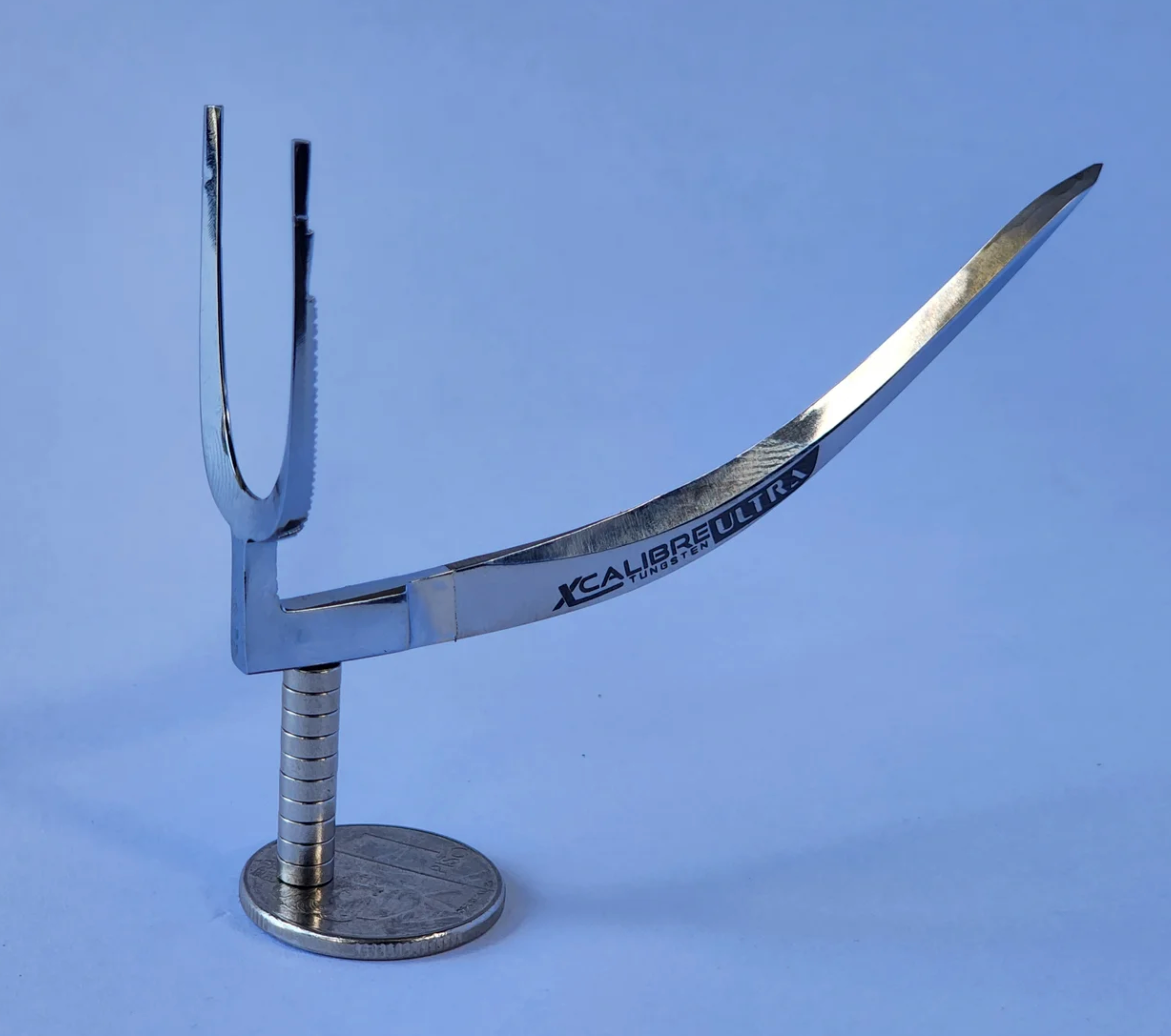

XCalibre Solingen Quality Steels

XCalibre Solingen Quality Steels are derived from European industrial blade steels known for their consistent metallurgy and controlled heat treatment behavior.

These steels are selected for knife applications that require:

- Balanced hardness and toughness

- Predictable performance within 60–62 HRC

- Stable, fine-grain microstructure

- Reliable edge retention without excessive brittleness

Rather than pushing hardness to extremes, Solingen-quality steels focus on usable performance—supporting thin, sharp edges while maintaining durability under real-world use.

This makes XCalibre Solingen Quality Steels well-suited for knives where consistency, control, and reliability are just as important as sharpness.